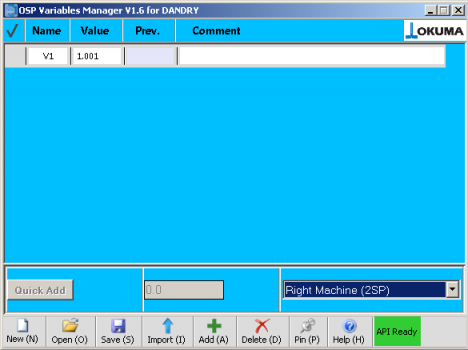

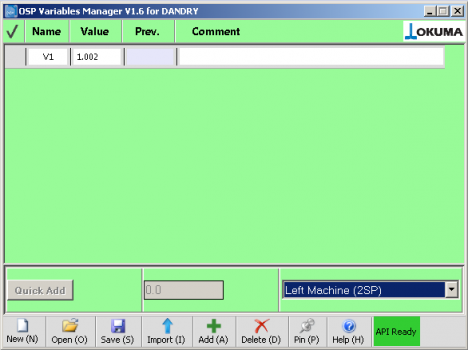

OSP Variables Manager

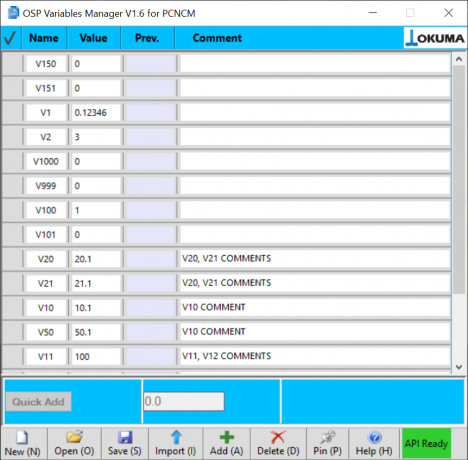

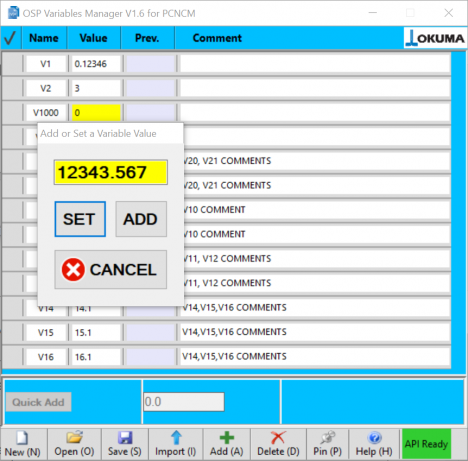

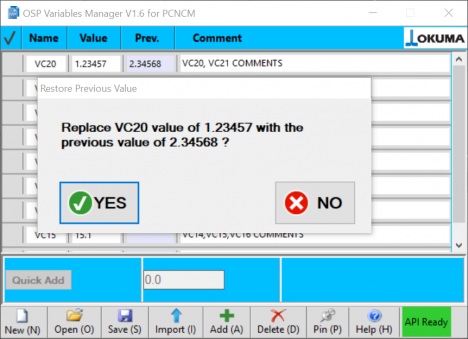

The OSP Variables Manager is a user friendly interface for working with common variables. It allows the user to focus on important variables, add comments to each variable, and revert to previous values. Variable values can be set directly, or by math operations. The import function automatically goes through the program to find the common variables used in it and adds them to the list.

Description

There is no longer a need to switch to the OSP Parameter - Common Variable page to work with variables. This application can automatically scan the part program selected for execution, find all the common variables used, and add them to its list. Set variable values or perform 'Quick Add' operations with 20 levels of 'Undo.'

- If the variable definition is followed by a comment (in the part program), the comment is automatically displayed in the variable comment field

- The variable list, with current and previous values and comments, can be saved to file for review or reloading

- Pin/unpin functionality to keep the application always visible

- Help button that shows a brief explanation of the icons and the basic functionality of the application

Details

Updated: 08/13/2021Available Versions: 1.6.0

Size: 120,457 KB

Functionality: Automation, Measurement/ Gauging

Compatibility:

- Operating Systems:

Win XP 32-bit SP3, Win 7 32-bit, Win 7 32-bit SP1, Win 10 64-bit

Other operating systems untested but may be compatible. - THINC API Versions:

For Grinders: 1.21.1.0 or later

For Lathes/Machining Centers: 1.9.1.0 or later - Dot NET Versions:

4.0 (included) - OSP Control Types:

OSP-P200 or later - Machine Types:

Works on all machine types, except standalone PC - Required License Features:

None

About The Developer

Company: Okuma America CorporationCertified Developer?

Phone: 704.588.7000

Email: api@okuma.com

Okuma America Corporation is the U.S.-based sales and service affiliate of Okuma Corporation, a world leader in CNC (computer numeric control) machine tools and machining process optimization. We’re the industry’s only single-source provider, with the CNC machine, drive, motors, encoders, spindle and CNC control all manufactured by Okuma. Along with our partners, Okuma delivers innovative, full-circle solutions for CNC machine tools, software and CNC controls. We’re there for you, wherever you are, providing lifetime access to the industry’s largest, independently-owned distributor network, ready to support your parts and service needs.

App Feedback

Related Documents

Average Overall Rating

2 Reviews

2 Reviews

thank you for downloading, testing the OSP Variable Manager and leaving a review. This kind of feedback is exactly what we need for improving our Apps.

We will add the functionality you are requesting, so the toolbar can be hidden/showed. Stay tuned for the next release!

CONS: The one thing stopping me from using this App right now is that I cannot lock or hide the toolbar. While one of my operators was testing it, he accidentally hit the "new" button and wiped out everything. I realize I can just reload the .var from MD1 but not all of my operators would get that (for some, the sky would be falling!)

I look forward to seeing the next version of this. We have over 50 machines running P200 controls and I think we will likely be using this on all of them eventually.