STEP-NC Machine

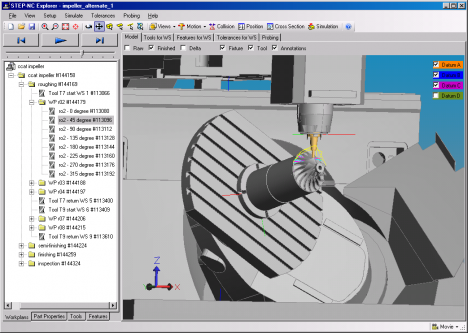

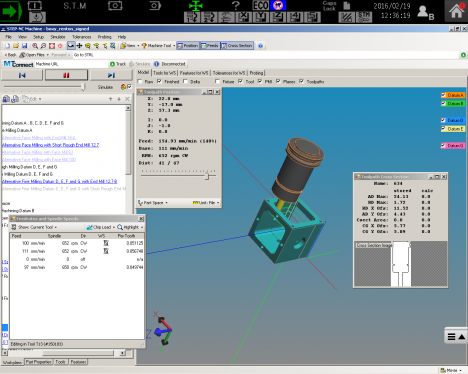

STEP-NC Machine® enables machining directly from a 3D model instead of the antiquated G-codes. It is new technology but when fully deployed you will no longer need a post processor, and you will be able to get third parties, such as cutter vendors, to optimize your programs.

Description

The G-codes defined by RS274D have been in place for over 50 years. They were ideal for a world of paper tape readers but they could not be replaced until computer graphics became fast enough to simulate machining in real time. That day is here!

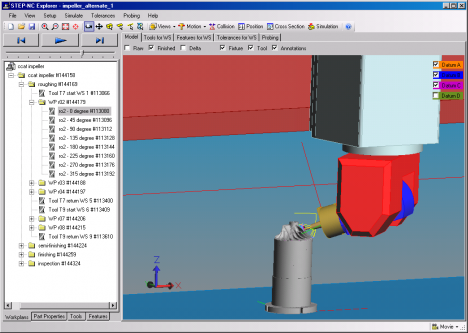

Using new standards you can replace the G-codes with 3D models that show you what you are going to make – the product including the required geometry, dimensions and tolerances; the process that is going to do the making – the tool paths, features and operations; and the solutions assumed by the process – the machine, the fixtures and the cutters.

Why should I care? Well if you are machining from models then you can check and correct your programs in real time. With STEP-NC Machine® you can both measure the part, and predict upcoming results. You can make test cuts, set 5-axis compensations, and evaluate how much material should be removed in the next pass by comparing the predicted results against the required tolerances.

MoreThe STEP-NC AP238 standard is the result of a ten year international effort to replace the RS274D (ISO 6983) M and G code standard with a modern associative language that connects the CAD design data used to determine the machining requirements for an operation with the CAM process data that solves those requirements.

STEP-NC builds on the previous ten year effort to develop the STEP neutral data standard for CAD data, and uses the modern geometric constructs in that standard to define device independent tool paths, and CAM independent volume removal features. STEP-NC allows manufacturing organizations to seamlessly share machining and measurement information between machines and over the Internet. The emerging STEP-NC technology is yielding process improvements including a 15% reduction in machining time, and a 35% reduction in planning time. The automated measurement and compensation enabled by STEP-NC promises to yield parts that meet higher accuracy requirements for less cost. The integrated simulation and verification enabled by STEP-NC promises to guarantee that every part will be made correctly and that production will stop whenever cuts are about to be made that do not meets design requirements.

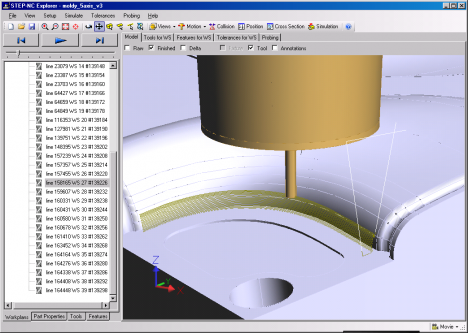

STEP-NC changes the way that manufacturing is done by defining data as "working steps": a library of specific operations that might be performed on a CNC machine tool. In other words, it breaks down every machining operation into the steps required to perform the operation. In the past, CNC machine tools had to be programmed using G and M codes (from ISO 6983), which were instructions that only told the machine what moves to make, without any semantic content that referred to the part being processed. STEP-NC will make G and M codes obsolete.

With the concept of "working steps" in place, the manufacturing process becomes streamlined. Now, a machine tool can receive a file with STEP-NC data, "know" what it means, and proceed milling the piece without any more instructions. There will be no more programming the machine tool for each individual piece. Moreover, the benefit of the standard goes further. With a set of standard "working steps" in place, all manufacturers will be able to share information reliably and instantaneously. A STEP-NC converted CAD file that is completed on the east coast can be sent over the internet to a machine shop on the west coast and they can immediately start milling the part.

Details

Updated: 02/19/2016Available Versions: 11.64.0.0

Size: 54,620 KB

Compatibility:

- Operating Systems: Win XP 32-bit SP3, Win 7 32-bit SP1, Win 7 64-bit SP1

Other operating systems untested but may be compatible. - API Version: N/A

- .NET Versions: 4.0 Full, 4.5, 4.5.1, 4.5.2

- OSP Control Types (R type supported): Application is designed to be run on PC, but will run on the following control types:P200, P300, P300S

- Machine Types: Any

- Required License Features: N/A

About The Developer

Martin HardwickCompany: STEP Tools, Inc.

Phone: 518.687.2848

Email: info@steptools.com

We are tireless software developers who are committed to improving engineering with smart, open product model data. Since 1991 we have been helping companies use the ISO STEP and STEP-NC standards to exchange CAD, CAM, and CNC data and simplify worldwide design and manufacturing.

We produce the ST-Developer software development tools for building STEP, CIS/2, or IFC support into any application. Strictly by the numbers, ST-Developer represents two million lines of code, supporting three programming languages, thirteen platforms, eighteen compilers, with twenty years of development and testing in commercial CAD packages.

STEP-NC Machine is our software for creating, viewing, and machining with STEP-NC manufacturing data. It creates machining programs that can be shared between many organizations and reused on many different machines. This is our "new" product, under development for only ten years.

App Feedback

For more information about the installation process, please visit the following site:

Related Videos

Average Overall Rating

1 Review

1 Review

Comments

Interested In Being A Developer?

Are you interesting in becoming a developer? We'd love to hear from you!

Stay Informed

We'll keep you in the loop about new apps, events and other cool stuff.